How Tier 3 Design Delivers Cleaner Pipes, Lower Costs, and Greater Control

Most jetting tools look alike, but not all nozzles deliver the same results. Many standard models lose more energy to internal turbulence than they deliver to the blockage. In contrast, KEG Technologies’ Tier 3 nozzles are engineered for performance that’s not only precise but provably more efficient.

In this article, we’ll discuss what nozzle efficiency actually means, how KEG’s Tier 3 models outperform the industry standard, and why that difference matters in terms of water use, cleaning time, and equipment lifespan. We’ll also address the practical concerns, cost, compatibility, and use cases, so you can decide whether KEG is the right fit for your job.

Cost of Cleaning Inefficiency You Can’t See

You can clear a line with a basic nozzle. But it will take more water, more time, and more wear on your jetting unit. Low-efficiency nozzles, often operating below 60% hydraulic efficiency, scatter water in all directions. That lost energy means it takes longer to shift debris, especially on longer runs or in lines with sediment build-up. It also forces your team to make repeat passes.

Here’s what that inefficiency really costs:

- Increased water usage per shift

- Higher diesel fuel consumption

- Greater wear on pumps and hoses

- Extra crew time for rework

- More frequent tool replacements

In summary, it looks like progress on the surface, but it drains resources in the background. That’s where nozzle efficiency becomes a technical detail and a cost control mechanism.

What Efficiency Really Means in Jetting Tools

Hydraulic efficiency is the percentage of water energy that translates directly into cleaning power. The rest is lost to turbulence or misdirected flow. To standardise nozzle performance, the National Association of Sewer Service Companies (NASSCO) classifies nozzles by efficiency tier:

- Tier 1: <50%

- Tier 2: 50% to 80%

- Tier 3: >80%

KEG models consistently exceed 95%. That means nearly all the energy from your pump is focused on clearing the pipe, not swirling pointlessly behind the nozzle. This is what separates Tier 3 tools from everything else. It’s not about pressure; it’s about how efficiently that pressure is used.

Why KEG Nozzles Exceed the Standard

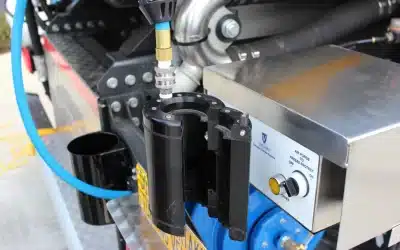

KEG nozzles are engineered with patented internal flow technology that directs water with exceptional precision. By reducing turbulence, more hydraulic energy reaches the target. That translates into better cleaning results with less water and fewer passes.

Each nozzle is fitted with replaceable titanium ceramic inserts, known for their longevity and resistance to wear. These ceramic inserts maintain performance over time and make maintenance easier and more cost-effective.

Three stand-out models include:

- KEG Royal: Built for large-diameter pipes (12″ to 48″). With 12 rear jets at a shallow angle, it delivers long-range cutting force ideal for sludge and debris.

- KEG Torpedo: Designed for 6″ to 16″ pipes, with a 97% efficiency rating. A workhorse for clearing sand, silt, and other sediment-heavy material.

- KEG OMG: Suitable for delicate infrastructure, corrugated, damaged, or concrete lines. Offers control and safety where aggressive flow could cause harm.

Each model is tuned for a specific task, but all share the same Tier 3 efficiency foundation. That consistency makes them suitable for both routine and heavy-duty work.

Where KEG Nozzles Deliver the Biggest Impact

No two pipe networks are the same, which is why nozzle selection matters. KEG nozzles aren’t designed to do everything, they’re designed to do the right thing, with less waste.

Here’s how they typically align with use cases:

- Royal: Ideal for trunk mains and large city infrastructure where heavy build-up is common

- Torpedo: Best suited for mid-range lines in residential and commercial zones

- OMG: For sensitive environments such as heritage pipes or post-repair areas

This isn’t just about powerful cleaning. It’s about purpose-built performance that makes better use of your time, equipment, and water.

Proving the Value in Operational Terms

The question isn’t whether a KEG nozzle works better. The question is whether the improved performance offsets the initial investment. Here’s how the value stacks up over time:

| Metric | Standard Nozzle | KEG Tier 3 Nozzle |

| Jetting passes per job | 2–3 | 1 |

| Water usage per shift | 10,000+ L | 6,000–7,000 L |

| Tool replacement cycle | 6–9 months | 3–5 years |

| Warranty cover | 1 year | 5 years (inserts), 3 years (tool body) |

| Labour hours saved monthly | 0 hours | 10–20 hours |

Every litre of water saved, and every unnecessary pass avoided, translates to tangible savings. Add in reduced tool turnover and vehicle wear, and the return-on-investment becomes hard to ignore.

Addressing Common Concerns with Practical Answers

“Is Tier 3 overkill for routine cleaning?”

No. Efficiency isn’t about high-pressure brute force, it’s about doing the job faster, with less resource draw. Even for regular maintenance, the gains are real.

“Isn’t the upfront cost too high?”

KEG nozzles do cost more. But the extended service life, reduced rework, and operational savings mean most teams recoup that investment within a year.

“Will it work with my jetter?”

In most cases, yes. KEG nozzles are compatible with standard fittings. If adapters are needed, KOR can advise and supply them.

“How do I choose the right one?

KOR’s technical team is here to help. From hose pressure to pipe material, we’ll make sure your nozzle matches your system.

Why KOR and KEG Are the Trusted Choice

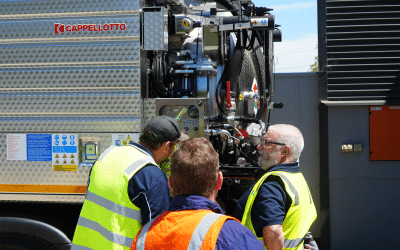

KOR is KEG’s exclusive distribution partner across Australia and New Zealand. That means when you work with us, you’re getting factory-backed insight, on-the-ground training, and practical support, before and after purchase.

We’ve supported councils, water authorities, and contractors for over a decade, helping them reduce downtime, extend asset life, and work smarter. Our partnership with KEG means we bring global performance standards into local, workable solutions.

Contact Us for the Right Nozzles

If your nozzles are costing more in time and water than they save in purchase price, it may be time to upgrade. KEG Tier 3 nozzles deliver the hydraulic control, durability, and reliability your crews need to clean smarter.

Explore KEG’s full nozzle range, or speak with our technical team to find the best nozzle for your needs.