Background

The Ohaaki Geothermal Power Station in New Zealand operates cooling towers that accumulate substantial sludge deposits at their base over time. Historically, de-sludging has been attempted only every four to eight years. Until recently, this meant sending crews into a high-risk confined space, relying on physically demanding manual labour to complete the task and workers being exposed to hazardous conditions.

Dormant sludge releases hydrogen sulphide, which is a toxic, highly flammable gas with a strong odour. The towers’ unique concrete hyperboloid design added another layer of difficulty, restricting access and making removal of sludge both physically demanding and logistically complex.

InterGroup are a leading industrial services provider with over 45 years of operational experience, and were tasked with finding a safer, more efficient solution. They have successfully deployed robotic cleaning systems for over two decades in hazardous environments such as the hydrocarbon tank infrastructure at Marsden Point in Whangarei.

The Gerotto robotic technology selected for this project was supplied by KOR Equipment Solutions, who are the exclusive distributor of Gerotto across Australia and New Zealand.

Challenge: Hazardous Working Conditions

The primary hazard in the Ohaaki towers was hydrogen sulphide. As the sludge remained dormant over years, this gas built up in the oxygen-poor environment and was ready to be released during disturbance. It posed the threats of being significant toxicity to workers and the risk of ignition.

Under manual methods, crews needed extensive personal protective equipment (PPE) and could only operate in short, closely monitored intervals. Operator fatigue was inevitable, requiring frequent crew changes. This meant more personnel, more shifts, and extended project timelines. Each additional hour spent in the tower increased operational cost and prolonged the cooling tower’s downtime.

The confined space amplified these issues. Heavy hoses, awkward manoeuvring, and poor visibility slowed progress and increased the strain on workers. Meeting both safety requirements and productivity targets in such conditions was a constant challenge.

Solution: Robotic Technology

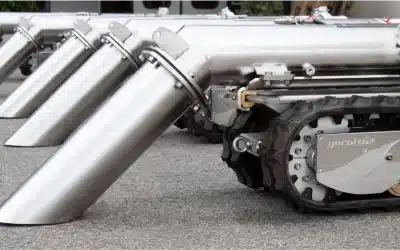

InterGroup deployed the Gerotto Lombrico S, which is a compact, tracked ROV engineered for hazardous, no-man-entry applications. Its robust, sealed body is capable of manoeuvring through confined, irregular structures while being remotely operated from a safe location outside the danger zone.

Equipped with a live video feed, operators could precisely control the ROV’s movements, guiding it to vacuum sludge directly into a waiting vacuum truck. The removed sludge was then treated with lime for stabilisation before being transported to InterGroup’s Auckland facility for processing and disposal.

This method removed the need for any manual entry into the hazardous zone. It also allowed for continuous operation, as the ROV did not require the rest periods or PPE changes that manual crews needed. Operators could work in shifts, maintaining productivity without placing personnel in harm’s way.

Project Results

The change in performance was substantial:

- Productivity – Increased from approximately 13–14 tonnes per shift using manual methods to around 50 tonnes per shift with the Gerotto Lombrico S.

- Crew Size – Reduced from 8 operators to 3, cutting labour requirements and associated costs.

- Operational Continuity – Enabled 24/7 operation without safety-driven stoppages.

- Risk Elimination – Removed the need for crew entry into the hydrogen sulphide environment, significantly lowering exposure risks.

The combination of increased throughput, reduced manpower, and enhanced safety resulted in faster project turnaround and earlier recommissioning of the cooling tower, meeting both operational and safety objectives.

Client Expectations

InterGroup’s client (Contact Energy) had a clear priority to remove the sludge efficiently without compromising worker safety. The Gerotto solution exceeded these expectations by delivering greater productivity, a smaller crew footprint, and a complete elimination of confined space entry.

Vian Smith, Head of Industrial at InterGroup, remarked:

“The Gerotto proved its value on this project, not only exceeding the client’s expectations but also delivering clear safety benefits. By removing the need for manual entry into the hazardous cooling tower our crew faced zero risk. This is a smarter, safer way of working.”

Learn More About the Gerotto ROVs

The Ohaaki project is a clear demonstration of how Gerotto ROV technology, supplied by KOR, can transform operations in hazardous, confined environments. By replacing manual entry with remotely operated systems, operators can:

- Maintain high productivity in dangerous conditions

- Remove personnel from direct exposure to harmful gases and unstable structures

- Complete projects faster and at lower total cost

For industrial cleaning, sludge removal, or confined space maintenance where safety and operational efficiency cannot be compromised, Gerotto ROVs offer a proven, world-class solution.

Explore the Gerotto Lombrico S in detail, or learn more about our Gerotto OEM partnership.