For water authority asset maintenance teams and civil contractors, few operational failures generate more frustration than a blown toilet. It’s not just about the mess, it’s the disruption and the complaints that follow. And the most confounding part? These incidents can occur even when everything is done by the book. This topic is rarely discussed in our industry yet poses a serious safety concern for residents in their own homes. Blown toilets are not isolated mishaps, they are a predictable result of pressure dynamics within sewer systems. Until recently, the tools to prevent them were either costly or cumbersome to deploy at scale. These limitations are where KEG nozzles excel.

Impact of Blowback in Sewer Lines

A blown toilet is the result of a pressure surge in a sewer line during high-pressure jetting. When debris isn’t cleared properly on the first pass, air becomes trapped between the nozzle and the obstruction. This air, under pressure, seeks the path of least resistance, which can be straight up a residential lateral line (sewer pipe). The outcome is unsanitary and leads to emergency callouts, clean-up costs, reputational damage, and a loss of trust. If anyone happens to be using the toilet at the time, it can be shocking and lead to serious injuries to that person. Teams find themselves sidelined with aftermath rather than progressing their planned maintenance schedules. However, it’s not always an operator issue, it’s an equipment limitation.

Why Standard Techniques Aren’t Enough

Blown toilets can also occur when:

- Jetting is done too quickly on the initial pass

- Upstream manholes are not opened, trapping air in the line

- The nozzle encounters accumulated debris and increases downstream pressure

The main issue lies in airflow and pressure dynamics, factors most tools on the market don’t adequately address. Even experienced operators using standard methods can trigger blowbacks without ever making a procedural error.

Proven Design, But Not Yet Scalable

KEG Technologies initially tackled this challenge with the Equaliser nozzle. Designed with twelve forward jets and six rear jets, it created an umbrella-shaped spray that blocked airflow towards laterals and significantly reduced the risk of blown toilets. The Equaliser became a specialised tool, often reserved for specific jobs or shared across fleets, making consistent prevention difficult. Therefore, the industry needed a solution that maintained technical excellence and also one that meets operational budgets.

Practical Evolution: The Toilet Tamer

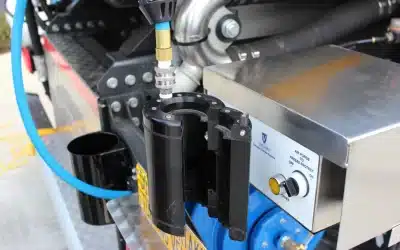

KEG responded by engineering a new nozzle designed specifically to eliminate blown toilets, without any financial and logistical limitations of earlier designs. The Toilet Tamer offers:

- A tapered, football-shaped body for easy movement through offset and misaligned pipes

- One forward jet and six high-efficiency rear jets that are angled at 30 and 40 degrees to disrupt airflow and prevent blowback

- Up to 90% water efficiency, allowing longer runs and fewer water tank refills

- Tier 3 classification, ensuring maximum cleaning capability

Most importantly, it’s more economically viable, and reasonably priced. Built with the same performance standards as KEG’s Tier 3 range, it offers a practical, fleet-wide solution for a long-standing issue.

Field-Tested and Operator Approved

In a controlled trial, the Toilet Tamer was tested in a 230mm pipe with a 150mm lateral. Typically, placing a hand over the lateral would reveal strong suction. This time, there was none. The testing team then ran the nozzle 100 metres upstream, leaving water pooled at the far end of the line. Even with that distance, the nozzle did not disturb the water, clear evidence that airflow had been eliminated. Potentially, operators can be equipped with the nozzle across multiple trucks, ensuring consistent protection during every cleaning job.

Addressing Any Potential Concerns

As this is a new product, here’s what operators and managers should know:

- It’s new and proven in the field: Designed by KEG Technologies, now trusted across Australia and New Zealand (through KOR), and validated by Water Authority / contractor use.

- Lower price, same standards: The cost savings come from manufacturing efficiencies, not from a compromise in material or design quality.

- Vast compatibility: Fits standard Australian jetting systems. No special fittings or conversions required.

- Minimal training required: Experienced operators can use it confidently. Optional support is available through KOR’s accredited training program.

And for those who haven’t yet experienced a blown toilet? This nozzle serves as a safeguard, mitigating a risk before it becomes a problem.

Standard for Modern Sewer Cleaning

Blown toilets are more than operational incidents, they’re a sign of system pressure imbalances that can now be solved. With the KEG Toilet Tamer, operators are no longer forced to choose between cost and capability. It’s affordable, field-tested, and built for the needs of municipal and contractor workflows. KOR’s exclusive partnership with KEG means this innovation is available across Australia and New Zealand, backed by service, training, and on-the-ground expertise. Contact us to speak with a KOR equipment specialist. Or learn more about our Drain and Sewer Cleaning Nozzles.