CAP VAC 2600 Dangerous Goods Liquid Tanker

The CAP VAC Dangerous Goods Liquid Tanker is a unit designed for Australia with a simple and ergonomic design.

With ATEX – Zone 1. explosion proof componentry and multi-class certification for: Classes 3, 4.1, 5.1, 6.1, 6.2, 8 and 9 the unit is rated for varied dangerous goods vacuum recovery operations.

Given the high quality components and safety standards included in the unit’s design, the CAP VAC 2600 DG LT improves safety around hazardous materials.

Application

Dangerous goods certification

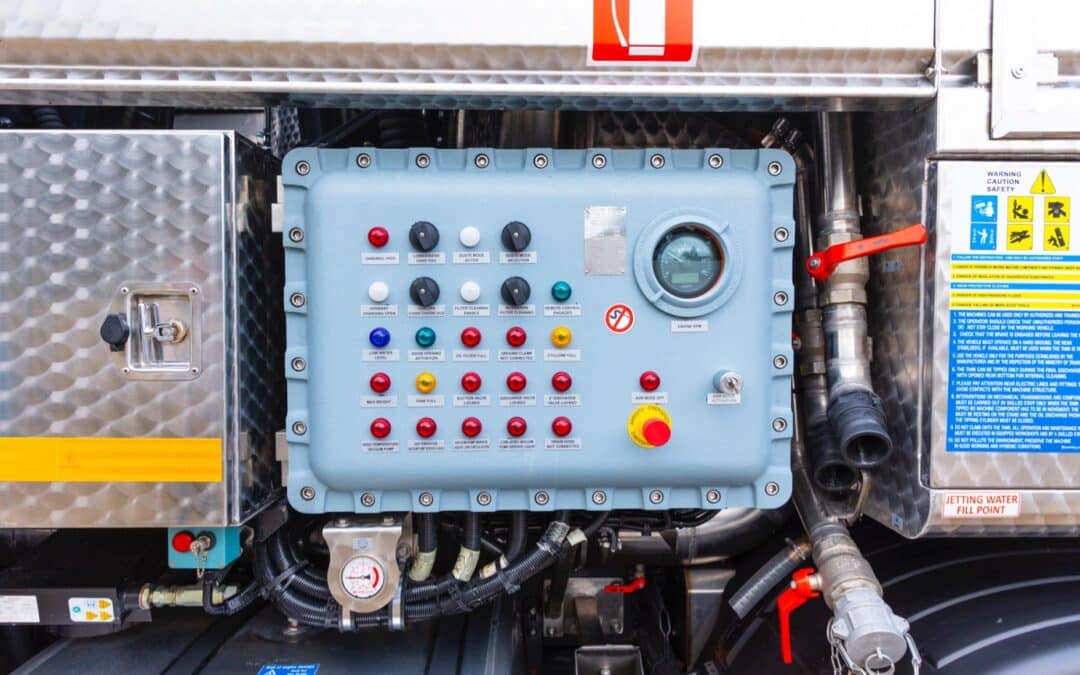

The CAP VAC 2600 Dangerous Goods Liquid Tanker holds multi-class certification for: Classes 3, 4.1, 5.1, 6.1, 6.2, 8, 9. The unit also has ATEX – Zone 1 certified explosion proof components including vacuum pump, control panel, sensors and suction/discharge valves.

Safety

Through the unit’s certification and design the highest possible safety level is achieved for the unit through design and specification specifically for Australia.

Versatility of applications

With a specification supporting a diverse range of applications, the unit becomes highly versatile and offers greater profitability to contractors. Applications including dangerous goods vacuum recovery, liquids vacuum recovery and hydro excavation.

Highlighted specs

Variant

CAP VAC 2600 Dangerous Goods Liquid Tanker

Chassis

Volvo FE320 6×4

Power (Hp)

320hp

Emissions

Euro 6

Wheelbase (Euro)

4,200mm

Turning Circle (Kerb to kerb)

17,100mm

Overall Length

9,050mm

Height

3,830mm

Sludge Tank

10,000 litres, Stainless Steel 304

Water Tank

1,000 litres, Stainless Steel 304

Vacuum Pump

Wittig Liquid Cooled Rotary Vane Pump with 1,600 m3/hr (940cfm)

Vacuum Efficiency

Max. vacuum 93% (27″Hg)

Vacuum Filtration

Stainless Steel Cyclone with automatic cleaning function

Vacuum Pump Safety Certification

ATEX Certified Zone 1 – Pump Only

Vacuum Exhaust Style

Vertical snorkel – automated operation with Stainless Steel 304 material

Hydro Excavation Pump

UDOR 17 l/min @ 280bar (4,061 psi)

Hydro Excavation Pump

Stainless Steel spring return 20m x 3/8″ hose

Control Panel

Rear Mounted Stainless Steel with all functions including unloading

Remote Control

Wireless with all functions including unloading

Tank Tipping

Hydraulically Operated

Rear Door Opening

Hydraulically Operated

Rear Door Suction Valve

4″ (100mm) Double Valved Stainless Steel 316

Rear Door Discharge Valve

4″ (100mm) Double Valved Stainless Steel 316

Sound Levels

Below 85 dB(A) at 1 metre at rear of unit (general working RPM at 1,000RPM)