Ultra high-pressure water jetting is common in the industrial cleaning and concrete demolition industry. Ranging from surface preparation, scabbling or concrete demolition. Despite its effectiveness, ultra high-pressure water jetting presents challenges such as operator fatigue, risk of accidental injury, and difficulty accessing confined spaces. These issues require innovative solutions like remote-controlled robotic systems, semi-robotics and enhanced training to ensure effective operation and worker safety.

KOR, in collaboration with Falch, are driving significant advancements in high-pressure and ultra high-pressure water blasting by introducing cutting-edge robotic systems and enhanced operator training. These innovations are addressing the industry’s challenges by making operations safer and more efficient while reducing the physical demands on operators.

Challenges in Ultra High & High-Pressure Water Jetting

Safety is a critical concern for employers and operators when using Ultra High and high-pressure water jetting systems. Physical strain and fatigue from handling high-pressure guns are common, as is the risk of injury from accidental jet exposure. Hazardous or confined areas add further danger, increasing the likelihood of accidents. These physical demands compromise worker safety and impact operational consistency by:

- Frequent breaks to manage operator fatigue increasing downtime

- Safety incidents that delay progress

- High manpower demands during labour shortages, making consistent operations difficult

Applications of Advanced Water Jetting

Safety and Productivity

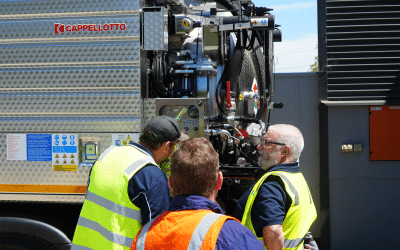

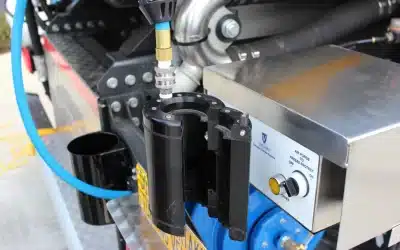

Robotic systems from Falch enables the handling of high-pressure tasks to be conducted in a safer manner. Operators are able to get the job done at a safer distance that takes away the reaction force from holding onto a high-pressure gun, while still offering precise control over the water jetting process.

Removing the operator from a hand gun can enhance safety and productivity by minimising reaction forces, reducing operator fatigue, and enabling longer, more focused work periods. These ergonomic advances help maintain continuous operation in challenging conditions, ultimately improving both worker safety and operational efficiency, while also having positive outcomes for operator job satisfaction.

Cost Savings and Operational Efficiency

Adopting advanced water jetting technologies can lead to lower healthcare costs due to fewer injuries and reduced operational expenses from minimised downtime. By reducing the need for direct operator involvement, companies can lower labour, insurance, and liability costs. The minimised safety-related downtime allows for longer, uninterrupted work periods, leading to faster project completion and lower operational expenses. These systems are particularly effective in high-risk industries, offering a sound investment that boosts both productivity and cost efficiency.

Training & Support for Operators

We’re committed to developing best-practice solutions for our customers through dedicated training packages. Our KOR training team offers tailored training programs, including our digital video program KOR Train, on-site equipment operation training, and inclusive unit training for larger fleets. KOR Train provides convenient mobile access to the latest information for safe and efficient equipment use, increasing productivity and reducing downtime. We also offer competency-based training in collaboration with an RTO, covering skills such as operating ultra high and high-pressure water jetting systems, drain cleaning, vacuum loading systems and hydro excavation, ensuring our operators meet and exceed industry standards.

Transforming Ultra High & High-Pressure Water Jetting with KOR

Working with our partners on advancing high-pressure water jetting technology has greatly improved safety and productivity. Explore our range of robotic systems, advanced water jetting tools, and tailored training options to see how we can help enhance your projects. View our products online or get in touch to schedule a demonstration today.