For municipal operators, utilities, and civil contractors, productivity isn’t always limited by skill deficiencies or poor planning, it’s lost in the extraneous costs. Refill stops, equipment fatigue, and sludge disposal are examples of delays and lost productivity. These interruptions are common, but there is a solution.

In an industry where operational efficiency, environmental compliance, and asset longevity are critical, the tools you choose have lasting impacts. That’s why organisations across Australia and New Zealand are turning to Cappellotto’s advanced water recycling technology, available exclusively through KOR.

Why Conventional Non-Recycling Sewer & Drain Cleaning Equipment Limit Productivity

Conventional sewer and drain cleaners have been the leading solution for sewer and stormwater network maintenance for years, but they carry inherent inefficiencies.

- No ability to recycle the water and sludge to re-use which could be utilised up to 15 cycles a day.

- Teams lose valuable time travelling to refill water tanks, requiring multiple times per shift, as a load of water can last as little as 30 minutes.

- Poorly filtered recycled water, if used at all, accelerates wear on pumps, hoses, and jetting nozzles, inflating maintenance costs and reducing asset life.

- De-watering in basic form, back down the drain without recycling the water then puts contaminants, sludge and silts back in the drain which the equipment is designed to remove, and not put back down the drain.

- Disposal of liquid sludge is cumbersome, time-consuming, and costly to handle.

These issues reduce job throughput, impact scheduling, and add costs across the lifecycle of each job. With compliance expectations increasing and budgets tightening, these inefficiencies are no longer sustainable.

Cappellotto’s Water Recycling System

The Cappellotto Recycler CAP RECY 3200 10×4 unit addresses these productivity limitations with a unique and versatile recycling system that operates continuously, under demanding conditions. The key benefits include:

- Continuous separation, filtration, and recycling of water on board, to a very small particle size, reducing the need for refill trips and minimising downtime.

- Production of water that is clean enough to protect pumps and underground assets from abrasive wear, thereby extending the life of the equipment and reducing maintenance costs

- Waste is discharged in a spadeable form, making disposal faster and more cost-effective.

With a 150% duty cycle and an 8,000-litre debris tank, this unit is engineered for high-output and high-uptime performance.

Cappellotto’s 5‑Stage Filtration Technology

No other water recycler in Australia matches the depth and efficiency of Cappellotto’s system. The 5 stages of separation and filtration are:

- Perforated Screen: Initial debris separation ensures larger solids are kept out of the system.

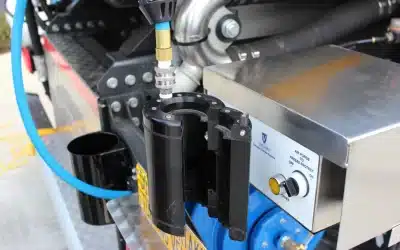

- Rotating Filter Drum: Self-cleaning, this drum filters material down to 100 microns, removing fine grit before it reaches sensitive components.

- Horizontal Cyclone: Centrifugal force separates heavier particles and redirects them to the debris tank (removing down to 50 microns).

- Five Sequential Water Tanks: These act as settling chambers, allowing fine sludge, organics, and foreign matter to separate before final filtration.

- Twin Vertical Water Cyclones: Up to 97% of PM10 particles and above. Clean water then feeds into the Uraca water pump, ensuring minimal wear from particulates.

This multi-stage process delivers industry-leading water clarity and extends the life of every component it touches. See the CAP RECY 3200 10×4 product page for full specifications.

Operational Gains for Civil and Municipal Fleets

The value of Cappellotto’s technology is clear in day-to-day operations:

- Refill-free shifts: Water recycling keeps crews working instead of travelling.

- Longer equipment life: Fine filtration protects pumps, nozzles, and jetting systems.

- Faster disposal: Spadeable waste reduces tipping time and disposal fees.

- Lower maintenance costs: Less abrasive wear means fewer repairs and replacements.

- Increased job capacity: More productive hours result in more completed jobs per week.

When servicing large-diameter drains and sewers, the Cappellotto Recycler 3200 enables faster, cleaner, and more efficient work.

Sustainability and Compliance

For water authorities, councils and contractors operating under strict environmental guidelines, Cappellotto’s water recycling system delivers meaningful advantages. It reduces freshwater consumption by reusing filtered water on board. This minimises environmental impact while cutting operating costs. Less water in equals less water out, reducing volumes for disposal and simplifying EPA compliance.

Common Questions and Answers

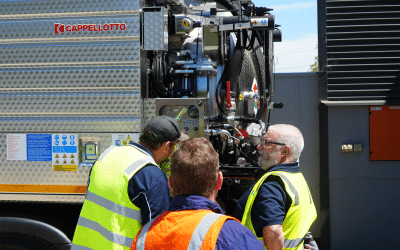

“Isn’t this system more complicated to operate?” No. KOR provides equipment familiarisation sessions to ensure operators can confidently run and maintain the system. Most crews adapt quickly and report improved workflows.

“Is the investment worth it?” Yes, productivity is typically 100% higher per shift compared to a non-recycling version. When viewed through the lens of total cost of ownership and productivity for the asset owner in. Water savings, reduced maintenance, less downtime, and twice the productivity combine to deliver strong ROI over the equipment lifecycle. Lease-to-own options are also available through KOR.

Why KOR is the Trusted Partner for Cappellotto

Since 2011, KOR has been supporting infrastructure Owners and contractors across Australia and New Zealand with world-class industrial equipment and end-to-end service.

As the exclusive distributor of Cappellotto equipment, KOR delivers not just the Cappellotto CAP RECY 3200 10×4, but everything required to ensure its success in your fleet, technical guidance, operator training, nationwide servicing, and fast access to genuine spare parts.

With service branches and mobile service and support units across the country, KOR keeps operations running and downtime low. Explore our training and servicing capabilities.

Contact KOR about a Better System for Demanding Industries

Operational excellence occurs through deliberate choices about equipment, service partners, and the technology you trust to get the job done.

Cappellotto’s 5-stage recycling technology, backed by KOR’s expertise, helps you cut downtime, protect critical assets, and meet performance targets, all while staying ahead of environmental expectations.

If you’re ready to explore how this system could transform your drain, sewer, or hydro excavation operations, get in touch with KOR.