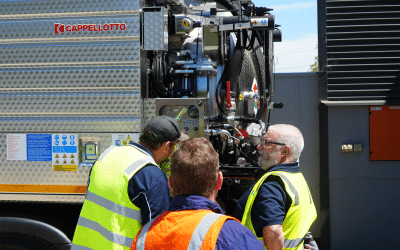

Operating specialised industrial equipment such as Cappellotto hydro excavation, vacuum and drain cleaning trucks that are built for performance, and precision is a skill set.

Operators need to be equipped with the knowledge, skills and competency to do their job safely and without the risk of injury to themselves or others nearby or potentially damaging equipment and company assets

KOR provides equipment refresher courses for existing operators, as it’s easy to mistake familiarity for competency. Operators may feel confident with the equipment they are using, but that doesn’t mean they are using it correctly, efficiently and safely. Important checks get skipped under pressure, and this erosion of best practice increases the risk of incidents, equipment damage, and lost productivity

What is it?

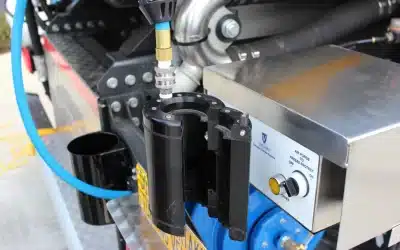

The course involves on-site training from KOR’s experienced application specialists and covers off using high pressure water jetting equipment, drain cleaning, vacuum loading and hydro excavations systems.

It also is used by some contractors who, when they purchase a new Cappellotto truck, require their operators to do hands on refresher courses to reverify their skills in operating that specific model. It also provides operators with adapting to new equipment features or modifications.

What are the benefits?

There are several benefits of operators undertaking an equipment induction refresher session that include:

- Improved safety and risk mitigation

- Helps remind operators of the potential hazards

- Reinforces safe operating procedures to prevent accidents or equipment damage and to minimise any downtime

- Maintains competency

- Assists operators in retaining and restoring existing skills and knowledge that may diminish over time

- It helps operators continue to perform at the standard required for safe and efficient operations.

- Better operator efficiency and productivity

- Operators can continue to use the equipment effectively

- Minimises downtime from misuse or inefficient operation

- Equipment longevity & lower maintenance costs

- Correct and proper equipment operation reduces wear and tear, so equipment lifespan is not compromised

- Fewer breakdowns or incidents because operators remember to continue doing pre-checks and routine maintenance

- Reduce risk of damage that could lead to expensive repairs or replacement

- Customer business and financial benefits

- Reduced costs from lost time, repairs, breakdowns

- Better productivity means more value from the equipment

- Potentially lower insurance claims can be claimed.

- Operator confidence remains

- Operators are confident with equipment applications & aware of the risks.

- Standard operating procedures are followed

- Regulatory changes

- Operators are updated on any changes on any safety regulatory changes

Setting Up An Equipment Refresher Induction

Organising an on-site refresher induction session for operators of Cappellotto equipment is easy:

- Determine what competencies you want operators to be re-assessed on – this could be areas vacuum operation, jetting, boom control

- Identify is there are any particular safety or risk areas such as dangerous goods or high-pressure water that need to be emphasised

- Contact KOR to schedule a session with requirements