CAP VAC 2600 Dangerous Goods Liquid Tanker

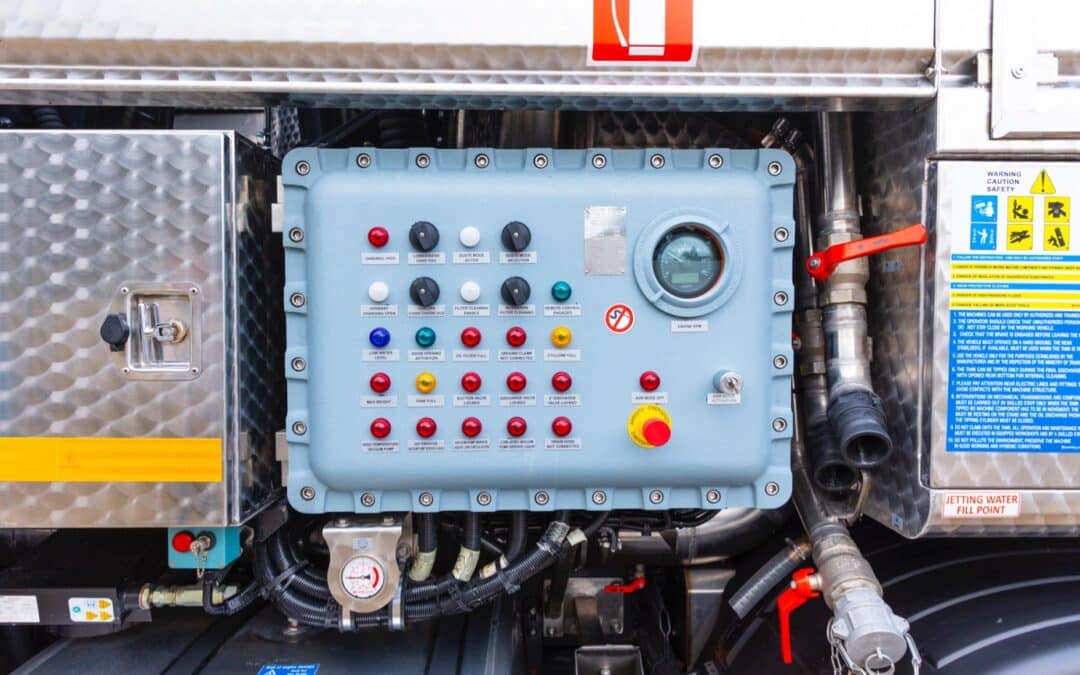

The CAP VAC Dangerous Goods Liquid Tanker is a unit designed for Australia with a simple and ergonomic design.

With ATEX – Zone 1. explosion proof componentry and multi-class certification for: Classes 3, 4.1, 5.1, 6.1, 6.2, 8 and 9 the unit is rated for varied dangerous goods vacuum recovery operations.

Given the high quality components and safety standards included in the unit’s design, the CAP VAC 2600 DG LT improves safety around hazardous materials.

Application

Dangerous goods certification

The CAP VAC 2600 Dangerous Goods Liquid Tanker holds multi-class certification for: Classes 3, 4.1, 5.1, 6.1, 6.2, 8, 9. The unit also has ATEX – Zone 1 certified explosion proof components including vacuum pump, control panel, sensors and suction/discharge valves.

Safety

Through the unit’s certification and design the highest possible safety level is achieved for the unit through design and specification specifically for Australia.

Versatility of applications

With a specification supporting a diverse range of applications, the unit becomes highly versatile and offers greater profitability to contractors. Applications including dangerous goods vacuum recovery, liquids vacuum recovery and hydro excavation.