Background

The Pantoro Mine Site, located in Western Australia’s Eastern Goldfields, required full internal coating removal from a 1,100 m² Carbon-in-Leach (CIL) tank. This infrastructure needed remediation of all internal surfaces, including walls, floor, baffles, and launders, following the failure of an existing polyurea liner. The removal was essential to ensure proper surface preparation for reapplication of a new polyurea lining system, meeting both performance and specification standards.

Six Solutions are a majority Indigenous-owned specialist service provider who were engaged to execute the work. Having only been in operation for just six months at the time, Six Solutions were chosen based on the extensive industry experience of its leadership team, strong client relationships, and a reputation for delivering efficient, safe and high-quality outcomes. Their core capabilities include ultra-high pressure (UHP) hydrodemolition, surface preparation, coating removal and concrete remediation.

Challenge: Navigating Confined Spaces

Working inside a large confined-space tank presented several challenges. Key among them was ensuring safe and efficient access to all internal surfaces, particularly around the baffles and launders, while controlling the water and slurry generated during the cleaning process.

The high-risk nature of manual UHP methods, such as using hand lances or rotary nozzles, also posed safety and fatigue concerns due to high reaction forces and intensive manual handling.

Additionally, the Pantoro Mine Site required all works to be completed within a five-day shutdown period. This placed further emphasis on productivity, operator safety, and reliable technology that could deliver results without compromising the project timeline or safety requirements.

Solution: The Falch Multiworker 250

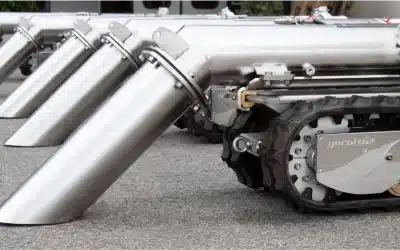

To meet the project’s requirements, Six Solutions collaborated with KOR to use a robotic, high-performance tool being the Falch Multiworker 250 (MW250). The MW250 is a UHP system designed for safe, efficient surface preparation.

KOR provided expert guidance on equipment setup, ensuring the Multiworker was optimally configured for the task. Operator training and safety briefings were also facilitated to align with confined space entry and emergency procedures, as well as the use of UHP equipment.

The MW250 was deployed via a scissor lift to access the vertical walls and complex internal features of the tank. Operating at pressures of 40,000 psi, the system enabled a high level of coating removal without imparting reaction force to the operator. This reduced physical strain and manual handling, while achieving a consistent surface finish across all internal surfaces.

The robotic nature of the Falch system also ensured greater productivity with fewer personnel, enhancing safety and reducing the risk of operator fatigue or error during extended operation.

Outcome: Efficiency Delivered & Safety Maintained

The project was successfully completed within the five-day shutdown window. All internal coatings were removed in accordance with the specifications, including the tank floor, walls, baffles and launders. The finish quality met surface preparation standards for polyurea reapplication, while maintaining strict safety controls throughout the operation.

The Pantoro Mine Site commended the Six Solutions project team on the quality of the result, the innovative and safe methodology, and the professional delivery of the entire scope within the designated timeframe. Importantly, there were no safety incidents, further reinforcing the robustness of the approach.

For Six Solutions, the project served as a demonstration of its robotic UHP capabilities. It strengthened their reputation as a capable and safety-focused contractor, and created a compelling reference for future projects across mining, industrial services and infrastructure.

“Using the Falch Multiworker 250 meant we could take a lot of the hard, dangerous manual work away from our team while lifting productivity. It’s the kind of smart, robotic UHP solution we want to be known for across the UHP industry.” Ammar Cheema – General Manager, Six Solutions Pty Ltd

Learn More About KOR

KOR has supported essential infrastructure, municipal and industrial sectors across Australia and New Zealand since 2011. As the exclusive distributor of Falch in the region, we enable partners like Six Solutions to adopt industry-leading UHP systems that prioritise safety, productivity and reliability. Learn more about our Falch partnership and high pressure water jetting equipment.

Our offering extends beyond equipment supply, with comprehensive operator training through KOR Academy (delivered in partnership with Trainright, RTO 45777), nationwide servicing capabilities, parts and accessories, and flexible leasing options to keep operations running.

To explore how KOR can support your next project, contact your local KOR office.