If you operate Cappellotto vacuum & hydro excavation units that are experiencing reduced suction or jetting performance, reliability issues, or general wear and tear over many years, there’s an alternative to full replacement. Refurbishment, when executed with OEM insight, restores your equipment to high performance, often at a significantly lower cost.

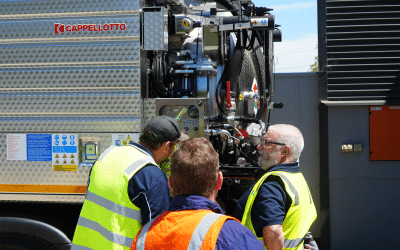

KOR refurbishment is a specialised engineering process. As the exclusive distributor of Cappellotto equipment in Australia and New Zealand, we rebuild these units with unmatched technical expertise, purpose-built facilities, and national support.

Learn why refurbishment is a viable and strategic option, and how KOR helps operators extend the value and lifespan of their Cappellotto fleet without compromising on performance or reliability.

When Cappellotto Unit Replacement Isn’t an Option

Even the best-engineered machines are tested by years of tough operational demands. Over time, wear becomes inevitable as vacuum performance is reduced, water weakens, and electronics falter.

But full equipment replacement comes with challenges such as extended lead times, large capital outlays, and operational disruption. For councils, contractors, and fleet managers under cost or procurement pressure, this isn’t always feasible.

KOR offers refurbishment that extends the functional life of your Cappellotto unit, maintains its reliability, and keeps your operation functional, all without the timeline or financial impact of new equipment.

However, if replacement is the only option, we may have Pre-Owned Equipment that matches your requirements.

Refurbishment That Delivers High Performance

Refurbishment with KOR is not simply cosmetic. It’s a systematic rebuild of performance-critical systems, engineered to restore your equipment to factory-grade standards. KOR delivers a project scope that meets your expectations and budget. We work with you every step of the way to tailor the project to ensure the customer will get the best return on the refurbished equipment.

Every project can include:

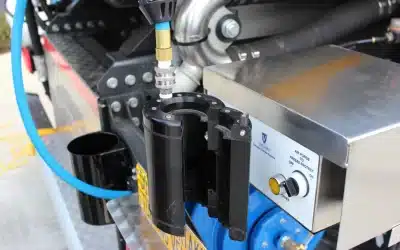

- Reconditioning of vacuum and water pump systems

- Replacement of worn or inefficient components

- Recommissioning of hydraulics, pneumatics, and electricals

- Tank repair or re-skin, if required

- Bodywork preparation and protective recoating

- Performance-tested prior to return

| Feature | New Unit | Refurbished by KOR |

| Cost | High capital expense | Significant savings |

| Lead Time | 4–6 months | Typically 4–6 weeks |

| Performance | OEM standard | OEM standard |

| Environmental Impact | High manufacturing footprint | Significantly reduced |

Backed by Experience, Powered by Engineering

Since 2011, KOR has worked with Cappellotto equipment across Australia and New Zealand. This partnership provides our team with:

- Access to OEM factory drawings and specifications

- Genuine Cappellotto parts

- Insight into model-specific engineering standards

- Direct collaboration with chassis OEMs for integrated refurbishments

Our technicians operate from dedicated engineering centres and mobile service units nationwide. Every refurbishment is completed under strict quality control, by professionals who know the Cappellotto range.

Learn more about our credentials via our Cappellotto OEM Partnership.

Upgrades for Smarter & Easier Operation

As part of the refurbishment process, many operators choose to integrate upgrades such as:

- New remote control systems

- New hardwired control panel

- Updated safety interlocks

- Easier-to-maintain electrical and hydraulic systems

- Renew of filtration systems

These updates help improve operational control, particularly for fleets with multiple operators or compliance-heavy contracts.

Responsible Engineering Meets Sustainable Investment

Refurbishment is a sustainability decision. Extending the service life of your fleet reduces the demand for raw materials, minimises landfill, and supports an economic approach to industrial asset management.

It’s a practical application of environmental responsibility, without compromising financials. For public sector procurement, it aligns with long-term sustainability objectives. For private contractors, it’s a smarter use of capital.

Common Questions and Answers

“What’s the risk of failure?” Minimal. All refurbished units are function-tested, and supported post-delivery. Warranty options are available.

“How long will my equipment be out of service?” Most refurbishments are completed in 4 to 6 weeks, subject to condition and parts availability. You’ll receive a clear schedule before any work begins.

“Is it cost-effective in the long term?” Yes. The refurbishment works that are completed ensure that the value of the equipment immediately increases and the ongoing cost of ownership decreases as the repair and maintenances reduces, with less unscheduled downtime in the coming years. These works are typically financed along with the complete unit for the 2nd life, so most contractors will see a reduction in monthly total cost over time once it is all packaged.

“What support do I get after the truck is returned?” You’ll have access to KOR’s national service network, mobile technicians, and spare parts inventory.

Trusted by Operators Across Australia and New Zealand

From municipal councils to national contractors, KOR has refurbished Cappellotto units for operators who value uptime, safety, and performance. Many have extended the lifespan of their fleet by 5–7 years, avoiding the need for replacement and maintaining operational continuity.

Restore Your Cappellotto to Peak Performance

Book an assessment today and discover how KOR can return your equipment to high performance, without the cost or delay of buying new units.

Request a consultation or contact our team to begin.