Every fleet manager has faced issues, such as a key piece of equipment stops mid-task. Crews wait, deadlines slip, and costs start mounting. Often the highest cost isn’t the fault itself but the slow, fragmented process that follows: misplaced manuals, uncertainty over the right part, and repeated calls to arrange service. In sectors like civil works, municipal services, and industrial maintenance, this scenario is far too common. Downtime cuts into productivity and erodes client confidence. To change that, after sales support needs to be faster, simpler, and more proactive. KOR Connect delivers that by combining our nationwide service network with a digital tool designed for the realities of the field.

Understanding the Cost of Downtime

Unplanned downtime is never just inconvenient. It can derail schedules, trigger contractual penalties, and require costly workarounds. For high-use equipment, every lost hour is one that asset is not earning. The longer it takes to diagnose and address the issue, the higher the operational and financial impact. Common causes include delays in accessing technical information, unclear communication between operators and maintenance teams, and time lost sourcing the correct part. Removing these obstacles is essential to keeping assets working and projects moving.

KOR’s After Sales Support

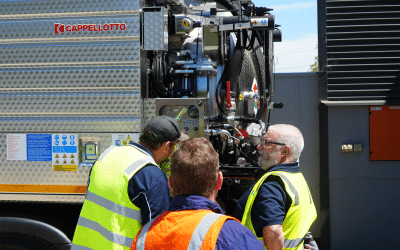

KOR is the exclusive distributor of Schwarze and Cappellotto equipment from across Australia and New Zealand and supports its customers with the infrastructure to keep their operations running, KOR has direct access to OEM specifications and technical expertise. Our nationwide network of workshops and mobile service vans provides coverage from metropolitan hubs to regional worksites. This is strengthened by RTO-accredited training delivered in partnership with Trainright, ensuring operators meet both safety and efficiency standards. KOR Connect builds on this foundation, extending support capability directly into the field.

How KOR Connect Works in Practice

Every KOR unit is fitted with a unique QR code, placed on the inside of the cabin door. One scan with a mobile device opens the gateway to that asset’s complete support environment:

- Operator manuals and service guides for immediate reference.

- Pre-start inspection forms built on OEM best practice.

- Digital service booking forms with the ability to attach photos or notes.

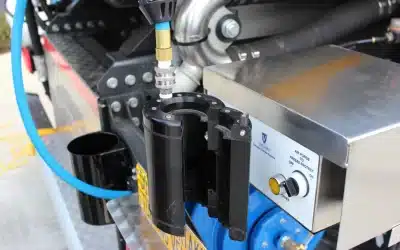

- Spare parts request forms with image upload for accuracy.

In addition, KOR Connect can provide live performance data, GPS location tracking, and predictive maintenance alerts to help prevent breakdowns with the installation of a powerful yet simple GPS device. All records are securely stored, creating a complete service history for compliance audits and incident investigations. The customer can log into their own customer portal to view the main dashboard with their equipment, showing utilisation, service and inspection records and vehicle location.

The Operational Advantages

KOR Connect centralises after sales support in one accessible platform. The benefits include:

| Traditional Support | With KOR Connect |

| Multiple calls and emails to request service | Single QR scan to log request with supporting images |

| Paper-based record-keeping for compliance | Automatic digital storage of inspections and service history |

| Delays confirming part numbers | Instant access to asset-specific parts request forms |

| Limited visibility on asset location and use | GPS tracking and utilisation data in real time |

For operators and fleet managers, this means less downtime, faster decision-making, and better utilisation of every asset.

Overcoming Common Concerns

Is it difficult to use? No. KOR Connect is designed for the field. A quick QR scan opens the relevant forms and resources instantly. Will training be required? Minimal onboarding is needed. Pre-start forms follow familiar OEM checklists, and KOR Academy training can be included to support adoption. We already have a maintenance system, so will this replace it? KOR Connect complements existing systems by providing mobile, asset-specific access and streamlining communication with the KOR service team. What about remote worksites with poor connectivity? If internet access is limited, inspections and requests can be saved and uploaded when a connection is available.

Safety and Compliance Without the Paperwork

Safety checks are only effective if they are consistent and recorded. KOR Connect ensures operators use OEM-based inspection templates and that completed forms are securely stored. This keeps fleets compliant with site and industry standards, while also providing a defensible record for audits and incident reviews.

In the Field: A Real-World Example

During a morning pre-start inspection, an operator spots a small hydraulic leak. They scan the unit’s QR code, select the inspection form, note the issue, and upload a photo. The fleet manager receives the alert instantly and contacts KOR. A technician is dispatched the same day, preventing a minor fault from becoming a costly breakdown. The service record is automatically added to the asset’s history, ready for future reference.

Moving from Reactive to Proactive Maintenance

Equipment support doesn’t need to be a waiting game. With KOR Connect, operators, managers, and service teams share the same accurate, asset-specific information in real time. This shift from reactive fixes to proactive care reduces downtime, improves compliance, and extends the working life of vital assets. Now is the time to close the gap between fault detection and resolution. Request a KOR Connect demo or speak with our After Sales team today and see what connected, proactive support can do for your operation.