In industrial cleaning, surface preparation, or concrete demolition, speed and precision matter. Yet for many operations, these come at a cost. Traditional ultra-high pressure (UHP) water jetting puts operators right at the source, battling intense reaction forces, fatigue, flying debris being blasted off the surface and reduced visibility from water mist. Each shift takes a physical toll, and each job carries risk. Safety managers know the consequences such as lost-time injuries, rising PPE expenses, and the need to meet strict compliance obligations under AS4233.1:2013 and Safe Work Australia guidelines. Add slower project turnaround and inconsistent surface coverage, and inefficiency becomes a costly habit. For years, this was simply accepted as part of the job, but it no longer has to be.

How robotics transform high pressure water jetting

Robotic high pressure water jetting ensures operators are removed from the hazard zone, and placed in full control from a safe, comfortable position. These systems deliver consistent, repeatable results without the fatigue that limits manual work. Remotely driven jet tools hold a precise distance from the surface, ensuring even coverage providing a consistent finish They are designed to safely work with significantly higher reaction force, allowing higher pressure flow combinations producing higher production. Falch water jetting machines work across floors, walls, ceilings, roofs, tunnels, even ship hulls, at speeds faster than conventional hand lance methods. Falch robotics are fast to set up and quickly moved or disassembled as the work requires. For projects where deadlines are tight and safety is non-negotiable, the difference is unmistakable.

Multi Worker 250 for versatile semi-automated cleaning

Transitioning from concept to equipment, the Multi Worker 250 shows how adaptability and safety can combine in one compact package. It is the lightest and fastest-to-assemble semi robotic unit in its class, making it ideal for time-sensitive or multi-location projects. It also offers multiple jetting modes, rotation, oscillation, and self-drive, to match different surfaces and cleaning patterns. Applications range from industrial cleaning and surface preparation to hydro demolition and coatings removal. Operators never touch pressure-bearing components, and the device absorbs reaction forces, reducing strain while maintaining productivity. The result is a safer working environment and evenly cleaned surfaces in less time.

Frame Rob 250 for fully automated high precision work

For larger-scale or high-precision requirements, the Frame Rob 250 provides fully automated, remote-controlled operation. Its flexible mounting options and extension kits allow it to cover expansive areas without constant repositioning, making it efficient for demanding schedules. This model excels in floor renovation, concrete scabbling or demolition, corrosion protection, and the cleaning of scaffold boards or form work It maintains uniform cleaning performance at higher speeds than manual techniques, offering a robust solution for continuous, heavy-duty operation.

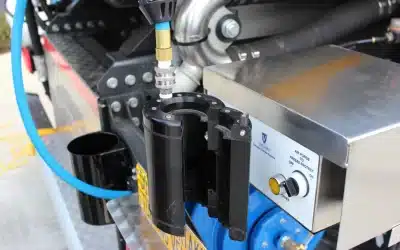

Surface Rob 250 for universal water jetting

The Surface Rob 250 brings true versatility to high pressure water jetting. Capable of working on floors, walls, and ceilings, it is equally effective for cleaning, roughening, or concrete scabbling or demolition. Lightweight yet capable, it integrates seamlessly with Falch accessory kits to expand functionality. For contractors and operators handling varied project types, it is a single piece of equipment that adapts to multiple roles. The Surface Rob 250 can be run either on a program or via a remote control unit. Unlike other devices of its kind, the remote can be used to make adjustments whilst running in program mode. This assists when operators are working on surfaces where the consistency changes, as travel and speeds can be adjusted. The Surface Rob 250 is the only robotic device where a trim option is available, which, when set, can follow the contour of a tank.

Trail Jet 125 as the mobile power source

Every robotic system needs a reliable power source, and the Trail Jet 125 delivers. This trailer-mounted, diesel-powered unit pairs seamlessly with the Falch range, offering adjustable pressures from 600 to 2,500 bar and high flow rates. Its large fuel and water capacity allows extended operation without interruption, making it well suited to hydro demolition, paint removal, and industrial cleaning where mobility is critical. The Trail Jet 125 enables the full performance potential of Falch robotics.

Safety and compliance benefits that protect people and projects

Falch robotics are built with safety as the first priority. Operators never handle pressure-bearing components, visibility is improved through reduced mist, and all reaction forces are absorbed by the equipment. These features align with AS4233.1:2013 and Safe Work Australia’s guidance, simplifying compliance. By reducing operator fatigue, they also improve morale and productivity, creating safer and more efficient worksites. The Trial Jet 125 is one of the few UHP pumps that is EURO 5 compliant, therefore meeting current emission control standards.

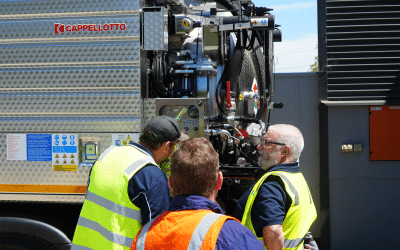

Training and support for lasting success

KOR ensures that technology is matched with capability. Through KOR Academy, in partnership with Trainright (RTO 45777), we deliver nationally accredited competency training for high pressure water jetting, drain cleaning, vacuum loading, and hydro excavation. Courses include hands-on, on-site instruction, with refresher programs to keep operators compliant and confident. Beyond training, our nationwide workshops and mobile service vans ensure parts, repairs, and technical support are always within reach, protecting uptime and productivity.

Overcoming common concerns about robotics

Even with the advantages clear, some decision-makers hesitate.

- Cost: Reduced labour hours, fewer injury claims, and faster completion times deliver measurable long-term savings.

- Complexity: Intuitive controls and accredited training ensure rapid operator proficiency.

- Versatility: Falch robots adapt to diverse surfaces, industries, and environments.

- Downtime risk: Our nationwide service network, stocked parts, and backup units keep projects on schedule.

Each concern is valid, and each has a proven, practical answer.

Real results from local worksites

Across Australia and New Zealand, robotic water jetting is already changing outcomes. Municipal crews have stripped coatings from large concrete areas without a single injury. Mining shutdowns have been completed in nearly half the anticipated time. On infrastructure projects, surface preparation has been faster and more precise, reducing rework and extending service life. These are not isolated successes; they are the results of integrating robotics into standard operating practice.

Taking the next step with KOR

Manual water jetting still has its place, but when safety, consistency, and speed are the priorities, robotics set a higher standard. Our exclusive range of Falch water jetting equipment delivers proven performance, supported by accredited training and a nationwide service network. Book a demonstration today and see how we can help you deliver safer, faster, and more consistent results on every project.