As urban expansion continues, the need for efficient and minimally invasive sewer infrastructure projects has never been greater. Traditional excavation methods often lead to significant surface disruption, prolonged project timelines, and increased costs. For complex projects like the Love Branch Sewer installation, a more advanced solution is required. Trenchless microtunnelling, supported by Cappellotto vacuum trucks, is proving to be the optimal approach, ensuring precision, efficiency, and minimal environmental impact.

About Pezzimenti Trenchless

Pezzimenti Trenchless have long been synonymous with pipeline construction and in particular focusing on sewer installations. This family business was established in 1957 as G Pezzimenti and Sons installing new sewers by conventional methods. It is now currently run by the 3 rd generation of Anthony, Stephen and Joe under Pezzimenti Trenchless who developed a laser-guided micro tunnelling machine in 1985. This quickly established them as leaders in the trenchless industry and they now operate throughout Victoria, SA and Tasmania with 7 full time crews. They have unparalleled experience and expertise working with many leading sewer and water contractors and have been involved with many major construction groups.

How Cappellotto Vacuum Trucks Transformed the Love Branch Sewer Project

The project name is the Love Branch Sewer and involves the laying of sewer pipes from Aurora Village to the Craigieburn Road sewage treatment pump station and is to be constructed by Yarra Valley Water’s delivery partner, MFJ Constructions (VIC) Pty Ltd.

The Love Branch Sewer Project in Wollert, Victoria, is an infrastructure development designed to service 2,400 commercial and residential properties and support the significant population growth forecasted for this Northern area. The project involves the installation of 1,850 meters of 718mm OD sewer lines using Pezzimenti Trenchless laser guided microtunnelling system.

When Pezzimenti Trenchless were commissioned by MFJ Constructions (VIC) Pty Ltd to perform trenchless construction on the project, there were several challenges to consider:

- Spoil Removal: The excavation process generates a high volume of spoil that must be removed efficiently to keep operations moving.

- Depth Considerations: At 14 meters below the surface, traditional excavation methods would be highly disruptive and impractical.

- Urban Impact: Open trenching in high-density areas would result in road closures, noise pollution, and potential environmental damage.

- Soil Stability: Managing groundwater and ensuring stability around boreholes is crucial to maintaining safety and project integrity.

Given these challenges, an alternative approach was necessary to ensure the project stayed on track while maintaining minimal impact on the surrounding environment.

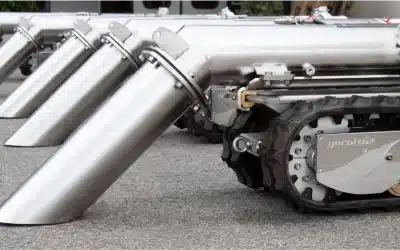

Powerful Vacuum Extraction for Microtunnelling

Cappellotto vacuum trucks played a critical role in overcoming these obstacles. Designed for high-powered vacuum extraction and hydro excavation, these units support trenchless microtunnelling by efficiently removing spoil from boreholes and maintaining optimal working conditions for the tunnelling process.

Advantages of Cappellotto

- High-Powered Vacuum System: The trucks provided the necessary suction force to remove soil and rock spoil efficiently from deep excavation sites.

- Hydro Excavation Technology: Integrated water jetting capabilities helped to liquefy spoil, reducing resistance and ensuring smooth extraction.

- Reduced Surface Disruption: By eliminating the need for extensive open-cut excavation, Cappellotto units helped keep roads and public areas undisturbed.

- Operational Efficiency: The ability to extract and transport spoil in a continuous process ensured that microtunnelling operations could proceed without delay.

Project Success with Cappellotto Vacuum Trucks

Pezzimenti Trenchless relied on Cappellotto’s vacuum extraction capabilities to maintain project efficiency. Given the varying ground conditions and project complexity, using high-performance vacuum units was essential in keeping operations streamlined.

Through seamless spoil removal and reduced downtime, the Love Branch Sewer Project has stayed on schedule. With bore lengths averaging 100 meters, maintaining a clear excavation path was crucial. The combination of precision microtunnelling and Cappellotto’s vacuum extraction technology ensured uninterrupted progress and minimised risk.

Why Pezzimenti Trenchless Partnered with KOR

KOR is the trusted supplier of Cappellotto vacuum trucks in Australia, offering industry-leading excavation technology and comprehensive support. Pezzimenti Trenchless chose KOR and Cappellotto due to:

- Unmatched Performance: Cappellotto trucks are designed for extreme excavation conditions.

- Full-Service Support: KOR provides ongoing service, training, and maintenance to keep equipment at peak performance.

- Proven Success: Trusted by other major contractors for large-scale infrastructure projects.

Pezzimenti Trenchless has consistently chosen KOR’s equipment for its reliability in demanding projects, solidifying our reputation as a leader in vacuum excavation solutions.

Contact KOR to Learn More

The success of the Love Branch Sewer Project demonstrates how advanced excavation solutions are transforming the industry. With infrastructure demands increasing, the ability to perform deep sewer installations efficiently and with minimal disruption is crucial. Cappellotto vacuum trucks, supported by KOR’s expertise, offer a future-proof solution for trenchless excavation.